Traceability - Innovative Solutions for Your Business

Meet SystemSmart - the leader in developing advanced Traceability systems. Our company is not only a technology provider, but also a space where passion meets innovation and experience turns into excellence. When you work with SystemSmart, you'll understand how cutting-edge technology can support the development of your production, regardless of your industry or specific requirements. Join us and see how technology can become a key element in the success of your business.

We provide Traceability Systems for:

Traceability - the key to full production traceability

A Traceability System, also known as a traceability system, is defined as “a collection of data and operations that enables key information about a product and its components to be maintained at each stage of the production and disposal chain”. This innovative approach to production flow management allows real-time collection and recording of data points. As a product moves through the production stages, the Traceability system monitors its movement from source to destination, ensuring full traceability.

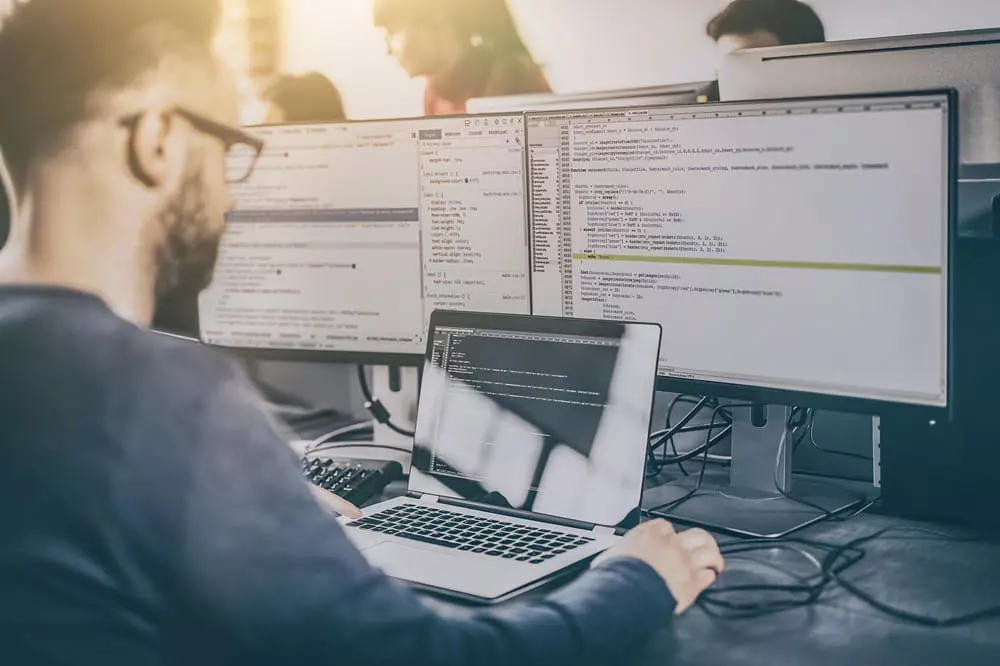

Specialists in Programming and Design of Automated Traceability Systems

SystemSmart is a team of experts in the programming and design of automated systems, in particular Traceability systems. In the world of industrial automation, System Traceability has become synonymous with professionalism and reliability. We specialise in industrial automation, offering comprehensive services covering machine automation.

Our offer includes:

Industrial automation

Advanced product tracking and traceability systems.

Machine automation

Optimisation of production processes through modern technological solutions.

Diversity of Traceability Systems

Traceability systems vary in their reach and level of sophistication. They can range from local systems within a single company, tracking supply chain transactions, to sophisticated platforms that monitor products at every stage of production.

A key element of Traceability systems is product identification, often implemented using barcodes or QR codes. These technologies enable precise tracking and recording of product movement in real time, providing full control and traceability throughout the production process. They enable high quality and compliance with standards at every stage of the supply chain.

Benefits of Implementing a Traceability System

Introducing a traceability system in a company enables goods to be monitored, allowing a rapid response in the event of errors and the necessary data to be collected. With the information obtained, a defective batch can be quickly recalled and the cause of the problem identified. The implementation of Traceability has many benefits for companies, both in terms of internal operations and risk mitigation, as well as in terms of market positioning. Some of the main advantages of a Traceability system are:

Ability to quickly recall the product if problems arise.

By accurately recalling the faulty batch, financial losses can be reduced.

Improved decision-making through better product identification.

Obtaining up-to-date information on available stock and different types of products.

Ability to better plan and manage the production process.

Strengthening the brand position by ensuring high quality and safe products.

The role of Traceability in Food Safety

TTraceability, or the ability to track assets during production and distribution, is crucial to food safety. Traceability systems have become increasingly important in recent years due to a number of emergency incidents in the food industry, highlighting the need to ensure the quality and safety of food products and their packaging for consumers.

Functions and Benefits of Tracking Systems

Traceability systems monitor products at every stage of the production and delivery process. When defects are detected, Traceability provides the necessary data to enable the rapid recall of the defective batch. It is not only a tool to keep companies safe, but also to respond effectively in the event of crises, protect against errors and improve production operations by identifying problems.

How Traceability supports Production Management

Traceability makes it possible to fully trace the production history of each product by means of continuous data logging. This information includes the origin of raw materials, auxiliary materials, production processes, packaging, transport and disposal. In this way, Traceability supports efficient production management, which translates into food safety and quality.

Implementing a Tracking System: Key to Improving Business Performance

Nowadays, Traceability is a key element for companies operating in any manufacturing sector. The growth in European markets and the increased export activity of Polish companies underlines the need for intelligent systems and procedures. Thanks to them, it is possible to ensure efficiency and safety at every stage of production, in accordance with international standards. The implementation of a traceability system therefore becomes an important competitive advantage for any manufacturing company, enabling it to streamline internal processes and adapt to new market requirements.

Traceability systems developed by SystemSmart are the result of extensive experience in the design of advanced IT strategies. Our solutions are developed with individual needs and requirements for traceability and production management in mind, using an integrated Traceability system. As a result, our customers can count on comprehensive and effective solutions that positively impact the productivity and competitiveness of their businesses.

Advantages of Proprietary Technology Solutions

Traceability systems are used in the automotive industry worldwide, in global factory complexes. That is why SystemSmart specialises in the design of sophisticated Traceability systems, created from scratch and customised to meet individual customer needs. With Traceability, information is automatically collected, processed, managed and evaluated, helping to increase productivity, improve quality, ensure safety and reduce production costs. Traceability is fully compliant with current legislation, providing companies with flexible tools to control and supervise products.

The benefits of Traceability SystemSmart include:

receiving raw materials, storage and distribution.